|

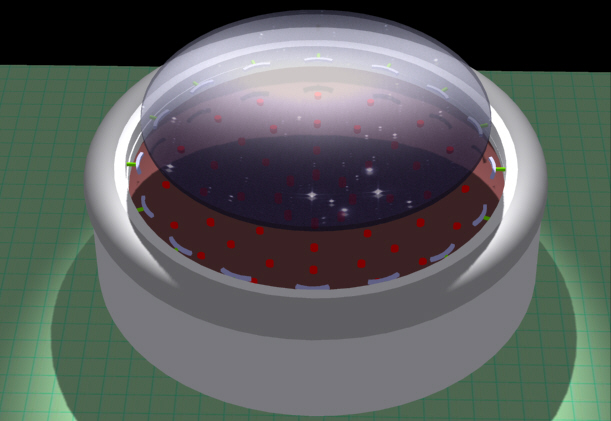

The Varifocal

Membrane Mirror

|

|

Human Intervention

I was thinking how it would be difficult

to assure that the images were coregistered, that is the same size and

focal length. I was thinking about how keeping a human in the loop

would make lining up consecutive images simpler [2].

Light Gathering Power

In the midst of all this I remembered an

idea I had been thinking about for a good while; A nice way to build cheap

telescopes with lots of light gathering power. Light Gathering Power is

directly proportional to the area of the mirror, which in turn is proportional

to the square of the radius. A large inexpensive mirror would be a great

asset for the amateur astronomer since it would enable the viewing of a

much fainter set of objects.

![[Graphics:indexgr4.gif]](indexgr3.gif)

Angular Resolution

The cousin of LGP, resolving power is linear

proportional to the diameter of the mirror. Resolving power, also known

as Angular Resolution determines how much detail can be seen, as in the

rings of Saturn for example.

Reflections On Palomar

Several decades ago, when the 200 inch Palomar

mirror was being cast it took 8 months for the glass to cool and over 11

years of shaping in the optical shops of CalTech[4]. At 14.5 tons it was

also quite heavy[5]. A membrane mirror can be made in a few hours. A membrane

mirror could be quite light. But a membrane might not pull into a perfect

parabola. It might not pull into a sphere. I became concerned that geometric

aberation would result when the mylar surface was deformed, that uncorrectable

artifact would contaminate the resulting images, making them unuseable.

Day Tripping

On the Wednesday following our trip to the

park I stopped by a local college. In front of the chalkboard I broached

the idea to the chairman of the astronomy department, Andre Rollefson.

The chairman shared my concern that geometric aberration was a significant

concern. He reminded me that Hubble had been corrected with downstream

optics, and jogged my own recollection of those events - I had been at

JPL while the modifications to the Wide Field Planetary camera were being

made. At this moment, in my mind, the shape of the downstream corrective

element became important. Area is plentiful in a membrane mirror, a few

points of Fstop lost through corrective elements are easily recovered by

making the mirror bigger. The chairman referred me to the assistant planetarium

director Charles Hemann. Beginning with my intention of an array of telescopes

and ending with suggesting a membrane mirror I repeated the argument, this

time on a steno pad. I asked him plainly. "if spherical aberration could

be rectified after the fact." He again mentioned that this was, "apparently

what had been done on Hubble." I was buoyed up by the realization that

I could perhaps build a huge flexible film mirror and then with a downstream

optical element correct for the artifact. It was during my sketching at

this second meeting that I realized one could digitally trade field of

view for signal to noise by simply tiling or compositing the images from

an array of optical telescopes. A mock up of this idea is shown using

a conventional image [6]:

Field of View Trade: 4 Mirror Configuration

- Wide Angle Tiling of 2 x 2 Array

|

|

|

|

Experimental Procedure

Before sinking a large sum of money in an

idea, it is often useful to build an inexpensive prototype, just to establish

feasibility and to identify trouble spots.

On the following Saturday, I took a coffee

can with a hole in the bottom and attached a plumbing fitting. A three

foot length of clear 1/4" vinyl tubing tubing connected this fitting to

a 50 cc syringe. The can was filled halfway with water.

The first surface was an oven bag which

was painted in place by misting with multiple applications of chrome spray

paint.

After the painted oven bag proved unsatisfactory (the reflectance was low) aluminized mylar film was stretched over the top and securing with a series of wide rubber bands. This initial method took two people, one to hold the membrane and one to place the rubber band. The mylar was then trimmed, the wrinkles were pulled out and black gaffer's tape was used to secure the film. Black gaffer's tape is a fine fabric tape resembling duct tape, but with a higher quality, less gooey adhesive. It can be torn into strips. When the water was withdrawn using the 50cc syringe, the image appeared bright and reasonably uniform. This crude varifocal mirror began to work. It was exciting.

A week later, while making the photographs for this article, a much easier method of attaching the membrane to the lip of the can that required no rubber bands, made a much better seal and did not use the gaffer's tape.

Observations

0) Obtaining a watertight seal at both the

fitting and the drumhead was nontrivial, requiring several attempts.

1) Stretching the film uniformly over the

rim -drumhead style- was quite difficult.

2) Bright chrome spray paint is dull gray

when applied to plastic.

3) With the painted oven bag, as the vacuum

was drawn, the reflectance appeared to drop as the concavity of the mirror

increased.

4) The reflectance of the aluminized mylar

also appeared to drop slightly when the film was placed in tension.

5)The smoothness of the mirror, and uniformity

of the surface improved with time as the mirror remained in tension.

6) Significant magnfication of the ceiling

could be produced by withdrawing water and pulling the membrane down. This

was no surprise. It was the intended effect. What was surprising was how

quickly and easily the focal length of the mirror could be changed... hydraulically.

7) There were fringes of distortion from

small defects in the rim at the edge of the membrane. These are visible

in the title picture above.

8) The unit is sensitive to barometric pressure,

air and water temperature.

9) With water in the unit as the principal

working fluid, tilted operation is limited. This restriction can

be relieved by using a larger syringe or a simple vacuum pump to withdraw

a greater volume of air.

Data Collection

These are crude first-order measurements but one must start

somwhere. The first order of business was to measure

the shape of the membrane mirror to determine what kind of geometric aberration

the stretched film would prefer. A flat metal ruler laid across the top,

bisected the tensile mirror. The image of the ruler yielded a good

reflection of the shape of the mirror surface.

To reduce perspective and parallax measurement errors, a piece of Lexan served to provide fixed plane of observation. Using electronic calipers we measured the distance from the ruler to its reflection with the Lexan sheet always enforcing the constraint of constant distance. The upper edge of the Lexan sheet is barely visible in the left photograph.

Placing the zero point exactly in the center our initial measurement showed that the reflected curve was symmetric to the tolerance of our measurements, about a quarter of a millimeter. With zero representing the center of our mirror, our raw data looks like the following. All units are in mm, read directly off the electronic calipers.

![[Graphics:indexgr14.gif]](indexgr14.gif)

This looks more reasonable.

Details

Now we are in a position to compare the

measured shape of our mirror to an ideal parabola. First we will define

a simple parabolic shape function with a coeffiecient we can tweak. Then

we will build a table of values that correspond to the exact x-ordinates

we measured above. Our choice of coordinate system makes the equation

for the profile of the idealized shape very simple:

Error Analysis

The measured membrane points are above and

below the ideal points to the following extents:

The error between the membrane and the ideal parabola is distributed both positively and negatively. Since the greatest error is still within the tolerance of our measurements, to first order, membrane appears close to the required shape. Typical astronomy quality mirrors are ground to a quarter to half a wavelength of light in accuracy, on the order of 200 nanometers. We are far from that level of accuracy in this, the first exploration of the idea. The results indicate that further work is justified and our three dollar prototype has served its purpose. More accurate methods of measuring the surface of the membrane will be required in subsequent attempts. But by that time we should be off the coffee can, and onto precision ground, truly circular rings.

Integrating Absolute Error Profile

To determine the best fit parabola we minimize

the total error across the face of the mirror subject to the constraint

of meeting the center and rim. Repeating the plot of the error above, but

this time with absolute value give us:

![[Graphics:indexgr22.gif]](indexgr22.gif)

![[Graphics:indexgr26.gif]](indexgr26.gif)

In the interval of x from -1 to 1 the sections appear to agree fairly closely. Let's look at the error relationship.

![[Graphics:indexgr28.gif]](indexgr28.gif)

The shape of this brief excursion error relationship is not the same as our measured example, so this refined attempt at explaining the error profile is not applicable at this crude level of measurement. Improved Ring Specification

Conclusions

Two models of the membrane mirror were built and

demonstrated. Initial measurements were taken and an analysis methodology

was developed and presented. Significant refinements in both construction

and measuring techniques will have to be applied. This simple proof of

concept

demonstration implies that the idea is worth pursuing further to the next

level of refinement with precision metal rings for membrane suspension.

It

has been suggested by Charles Rydel of Paris France that concentric high

voltage electrodes could be used to improve the shape of the membrane.

I propose extending

this further by adding a radially symmetric set of point electrodes to give

precise control of shape, as illustrated below. The applied voltages could

be controlled by a DSP chip and closed loop feedback system to produce

a time

averaged mirror of useable shape.

|

Other Questions

For a General Introduction see Ultimate Beginners Guide to Astronomy

References

[1] Yaeger, Larry and

Upson, Craig "Combining Physical and Visual Simulation - Creation of the

Planet Jupiter for the Film 2010", Computer Graphics, Volume 20,

Number 4, 1986, pps 85 - 93. esp p 86 Section 3 Paragraph 2.

[2] Views

of the Earth

Summary: The images used were taken

by CZCS (Coastal Zone Color Scanner) of NASA Nimbus

7 satellite. The images used

were taken by the NOAA weather satellites and knitted together by artist

Tom Van Sant and computer graphicist

Lloyd Van Warren for The Geosphere

project

[3] Various types of optical telescopes including Newtonian, Prime Focus, Cassegrain and CoudeŽ

[4] The

Palomar Observatory

Summary: Part 1 Part 2 Part 3 Part

4. FORWARD BACK HOME The Pyrex mirror was cast at

the Corning Glass Works in

New York in 1934. It took more than 11 years in the optical shops at

Caltech to figure the raw

piece of glass into the perfect surface it is today.

[5] Palomar

Observatory: Visitor Brochure

Summary: Even more significant

is the development of new electronic devices that sense faint signals

of light from distant celestial

objects. One of the reasons Palomar Mountain was selected as the site

for the 200-inch telescope

was its dark skies that would allow observation of the faintest galaxies

without the interference of

city lights.

[6] Astronomy

(Science)

Summary: Ben's Space Pages -- Linking

Hyper Space to Outer Space. Space

Telescope Electronic Information

System (Gopher).

[7] MATH

1509AC --- PROJECT 1

Summary: Namely, all light rays

parallel to the symmetry axis are reflected to pass a single focal

point. (i) All light rays parallel

to the symmetry axis of a parabolic mirror are reflected through a single

focus; (i) A spherical cap does

not bring light rays parallel to the symmetry axis to a single focus.

[8] Aluminised

Mylar as a Flux Collector

Summary: Aluminised Mylar as a

Flux CollectorThe telescope was first shown at an August 5, 1978, exhibition

meeting of the Southeast Group of Astronomical Societies, and again on August

26-27 at the Epsom Borough Show, in the booth of the Ewell Astronomical Society

(Maurice Gavin - Worcester Park - Surrey - England vice-chairman).